Monolithic catalysts of porous rare earth oxides (REO)

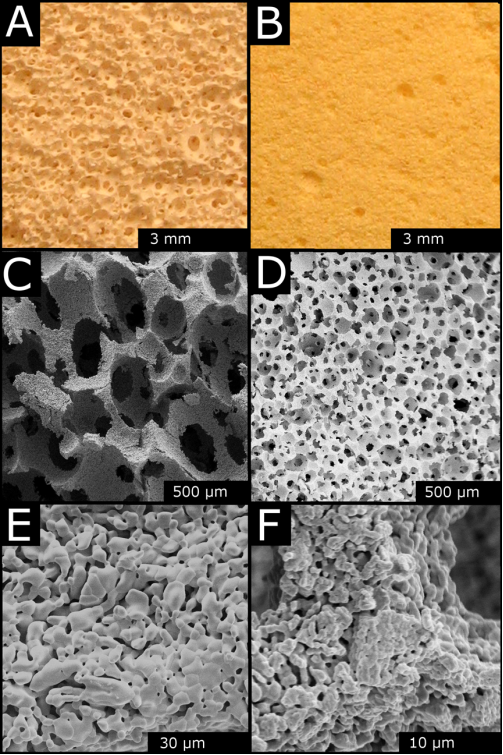

Although a lot of experience with packed bed reactors exists in chemical industry, problems with mass transport limitations are not unusual. Accordingly, new reactor concepts based on monolithic catalysts with a defined porosity have been proposed in recent literature. Macropores which may have dimensions up to the mm regime allow a passage of gas flow-through thus ensuring that all parts of the reactor take part in the reaction. If macro-, meso- and micropores ideally match, an optimal gas transport can be realized. An important prerequisite for such concepts are suitable materials with a hierarchical porosity which can be catalytically coated. In the present project, rare earth oxides (REO) are in the focus of interest, an efficient use of which is particularly important in view of rising world market prices. More specifically, REO coated monoliths shall be prepared and used for oxidative coupling of methane, exhaust catalysis and partial oxidation reactions (e.g. methanol). In the first place, it is planned to coat porous monoliths made from inert and cheap oxides, such as alumina e.g., with REOs by sol gel techniques. The catalytic performance in terms of activity and possibly selectivity will be compared to aero- and xerogels of the same materials in the form of powders. After having studied the properties of the pure REOs, it will be interesting to functionalize the systems further by depositing nanoparticles colloidally prepared from metals (such as Pt or Au), which are known to interact synergistically with REOs. Another way of depositing metals is given by gas phase deposition via CVD or ALD. Finally, also mixed REOs, e.g. praseodymia/ceria mixed systems, will be studied.